Collaborative Robots

History

Collaborative robots are new to the main stream robotic world. Twenty years ago manufacturing robots were used to perform operations that humans could not do easily. Spot welding the frames of vehicles on an assembly line or lifting bulky items that required multiple people to move. As robots became more affordable, it was feasible to use robots to perform jobs that people are good at also. It’s a quick payback to use one robot to perform the task of a 24-7 operation.

Click Here to continue article.

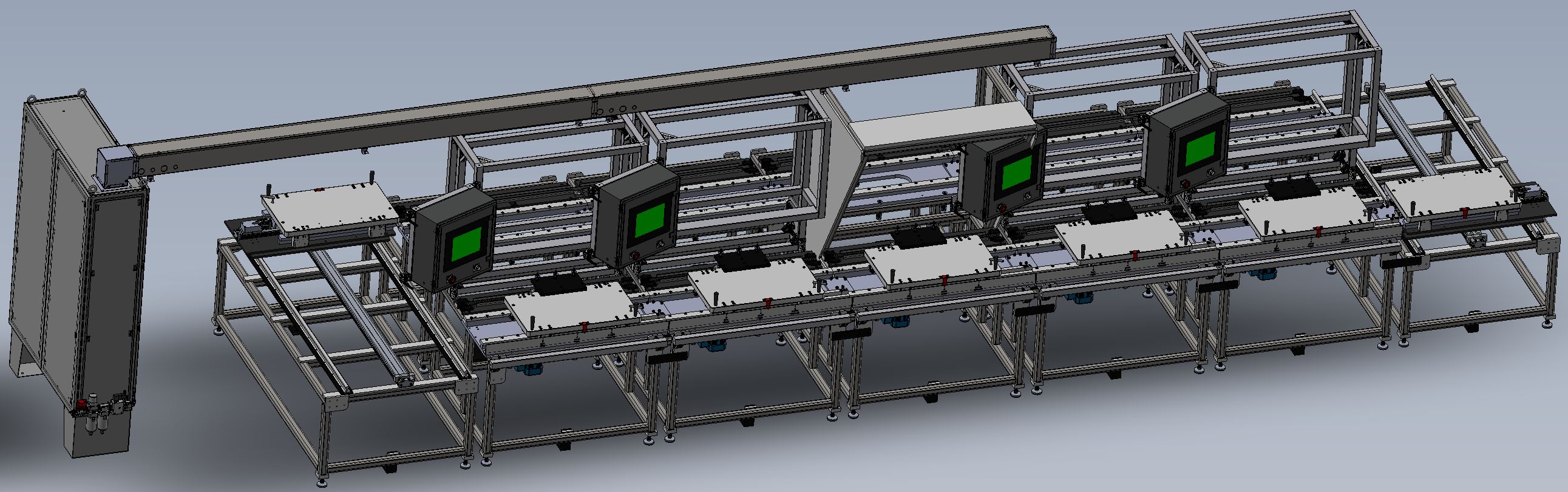

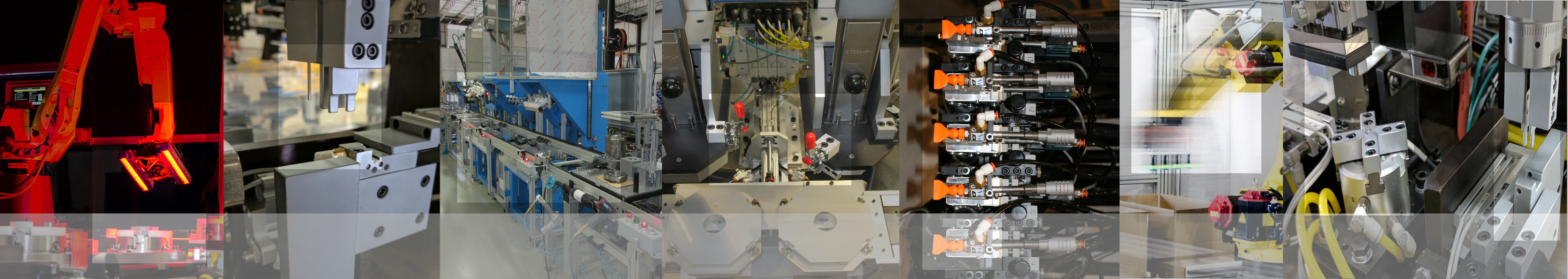

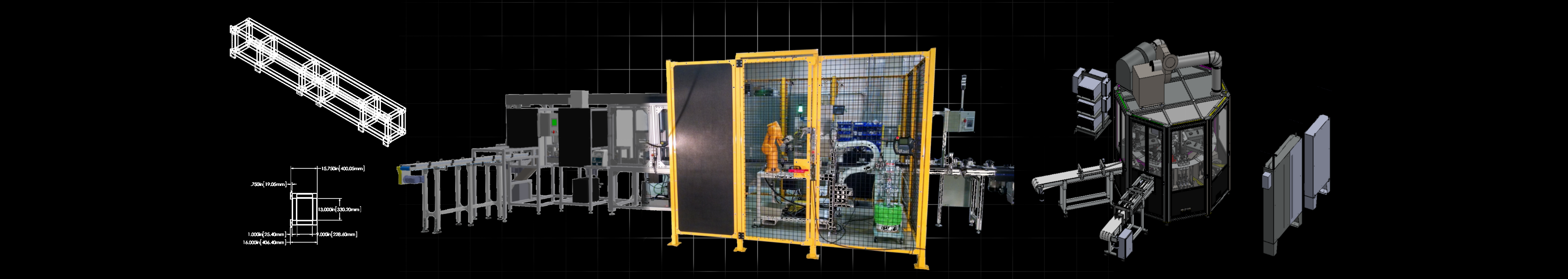

ProMATIC Automation is capable of automating a wide range of processes. We have nearly 20 years of experience automating these processes across a diverse cross section of industries like Automotive, Bio-medial, Manufacturing, Industrial, Heavy Construction, Commercial/Industrial Lighting, Hydraulic Power and Plastics Injection Molding.

- Assembly

- Inspection

- Dispensing

- Machining

- Electrical Testing

- Palletizing

- Locating

Watch this video to see an overview of the types of projects ProMATIC Automation has automated.

Progress

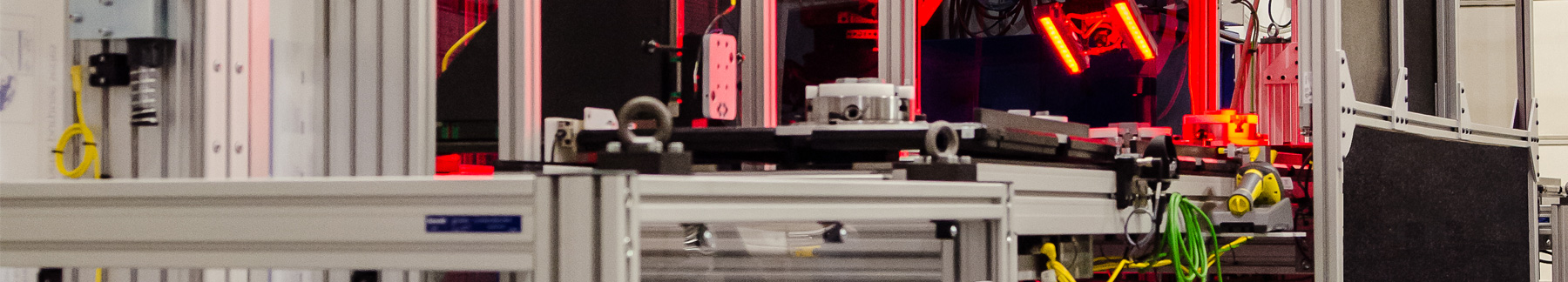

As robots replaced people, safety issues arose that are an unseen initial cost of using robots. A mid-range 6 axis robot can be purchased for $60-75,000. The cost of making a robot safe to work around can be an additional $20,000 or more. The guarding must be designed, the PLC programmed and the all components installed. Moreover guarding a robot takes up valuable floor space and this factor alone restricts where a robot can be used. One of the more recent developments in the robotic field are collaborative robots. As a result of the safety costs associated with standard robots, collaborative robots are a good solution to eliminate the “unseen initial costs” as well as saving time and money on setup and installation.

What is a collaborative Robot? Simply put, it is a robot that can collaborate with humans because it is safe to work around.

Since collaborative robots are safe to work around, they are a practical solution to use in locations that a standard robot would make unsafe. Another benefit is that the time from concept to implementation is reduced from weeks to days because no external safety devices are required. Eliminating the need for light curtains and guarding creates more opportunities to use robots.

Collaborate robots look and operate like a standard robot. Programming is similar and in some respects simpler than standard robots. Advances in the fields of force feed back, capacitive sensing, tremor sensing and safety scanners have allowed the development of this new type of robot.

Using force feedback a robot can detect if it has collided with another object. A capacitive skin detects contact with humans. Tremor sensors detect if a person is walking in close proximity to the robot and safety scanners can be used in some situations to allow the robot to operate at faster speeds when the danger zone is clear. There are a wide range of robots available with sizes and payload capacities that are suitable for applications currently up to 65 kilos.

Considerations

Light and medium duty robots are ideal for machine tending. The size and weight make them easy to transport and deploy to another task. Several robot manufactures include manual manipulation teach modes which reduces setup time and is easy to program.

Larger models can handle boxes for loading pallets or assist an assembly line worker with positioning heavy components.

EOAT configurations are still a concern for safety. Calculations are required to determine the max safe speed the robot can manipulate the EOAT.

Prior to purchasing a collaborative robot for a project, a time study is required. Cost savings are a major deciding factor but cycle time also will be especially relevant. Collaborative robots must run at notably lower speeds. Higher speeds require longer deceleration times that create an unsafe environment. If the robot can not meet safety standards then guarding is required.

Consider these advantages and disadvantages to help determine if your project could benefit from a collaborative robot.

Advantages

- No Guarding Required

- Safe to Work Around

- No Safety Equipment Required

- Quicker Startup

- Lower Startup Costs

- Easy Programming

- Fast & Flexible Redeployment

- Quicker Payback

- Move after Contact

- Robot Cost

Disadvantages

- Slower Speeds

- Lower Payload

- Limited EOAT (End of Arm Tools) Capability

Practical Uses

- Assembly

- Packing

- Machine Tending

- Palletizing

- Inspection

Conclusion

The advantages to collaborative robots are numerous but currently the disadvantages, though few, are critical to the manufacturing environment. The future outlook for collaborative robots is strong. They will not be suited for every task but there are currently a wide range of practical uses for them. Expect to see collaborative robots with higher payloads and faster safe speeds around humans as they gain popularity.