Rotary Dial Machines

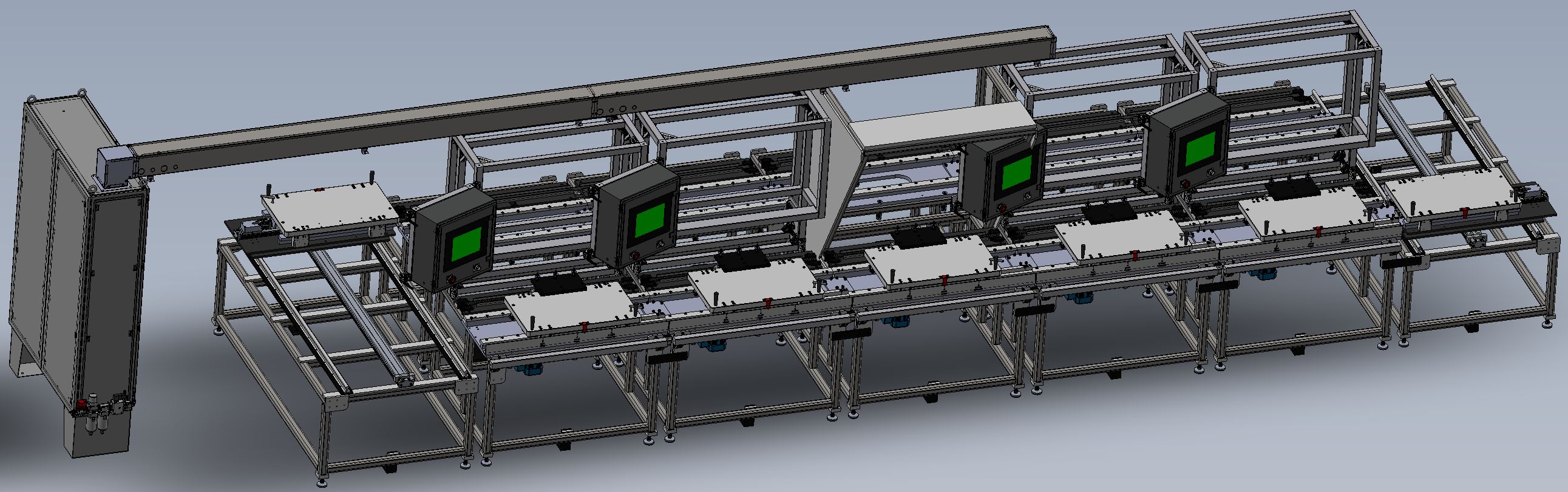

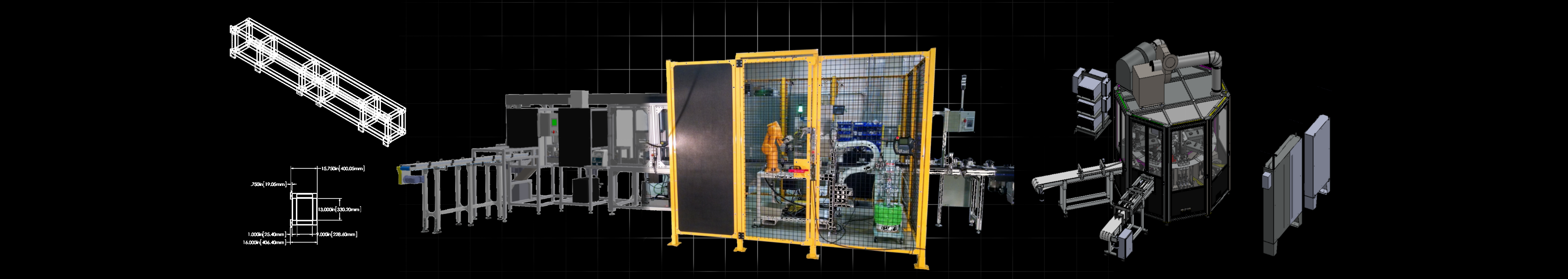

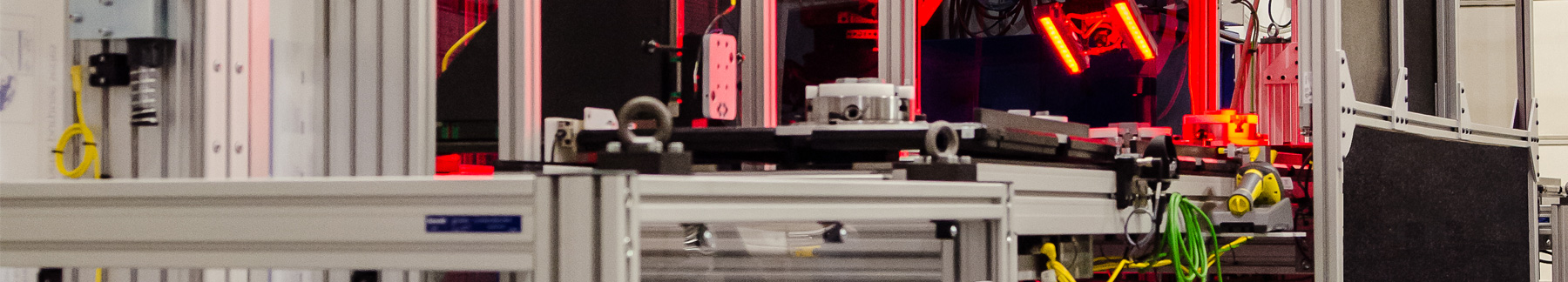

The ProDIAL machine platform is a version of synchronous machine with low cycle time capability and small footprint, where primary machine operations take place on a common dial plate with multiple operational stations whose motion is controlled by a rotary indexer.

Parts are delivered to the ProDial Machines using vibratory feeders, pick and place devices, and operators. Station tooling is mounted on stationary datum surfaces to provide precise and repeatable operations for high quality results. Completed components/assemblies can be automatically unloaded to finished containers or conveyors for further processing.

ProDial Advantages

- Relatively Low Cost

- Highly Repeatable Operations

- Short Cycle Times

- Compact Machine

- Flexible Design

- Fully Automatic or Semi-Automatic

- Long-Term Reliability of Performance

ProDial Common Functional Operations

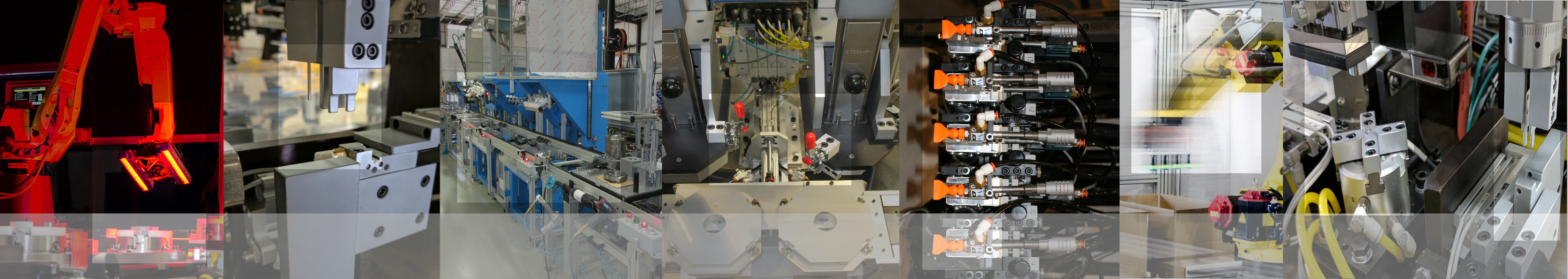

Leading automation technologies are utilized at each station (robotics, lasers, dispensing systems, vision systems, IR heating, drilling units, servo presses, torque devices, pneumatic and hydraulic mechanisms, etc…) to provide high-tech assembly/processing solutions.

- Dispensing

- Machining

- Inspection / Testing

- Assembly

- Pressing

- Torque Control

- Measuring

- Marking

- Heat Staking

- Ultrasonic Welding