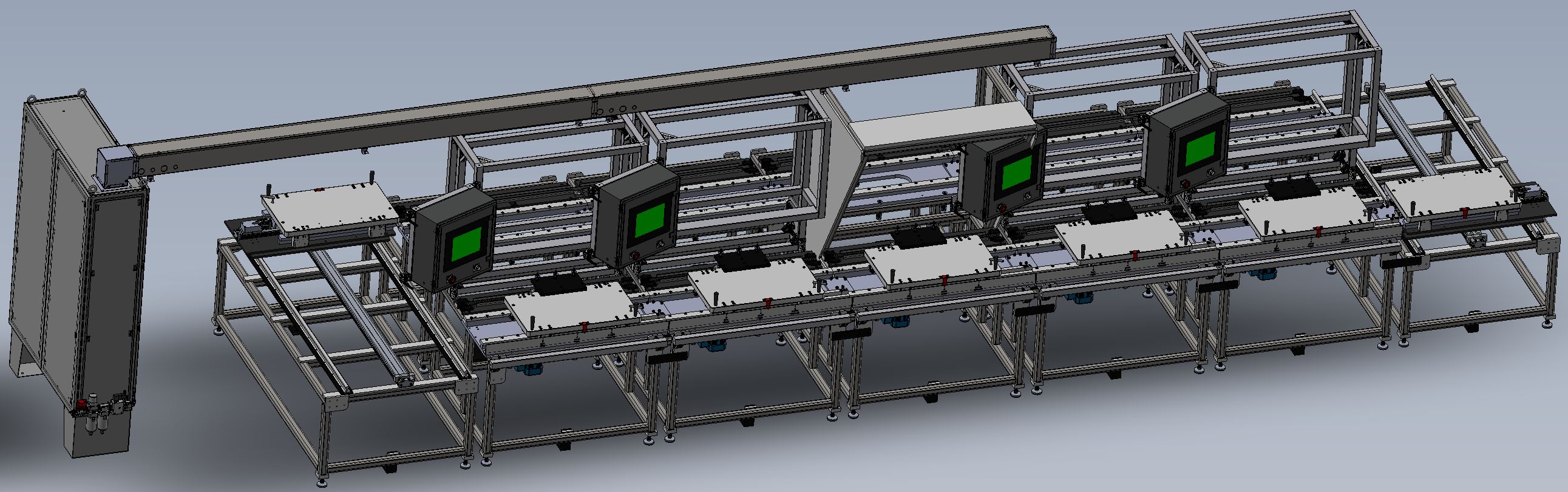

ProMATIC Automation Expertise

30 Second Overview of Machines

ProMATIC Automation designs and builds assembly and test equipment for a broad cross section of industries.

ProMATIC Automation is a full service custom machine builder. We are experienced in integrating components from a long list of manufactures to create an automated system that is built for our customers specific needs. Here is a list of manufacturers we frequently use.

Mechanical

- Fanuc Robotics

- Motoman / Yaskawa Robotics

- Camco Indexer

- Bosch Conveyors

- Keyence Laser Markers

- Trump Laser Markers

- Tox Pressotechnik Cylinders

- Schunk Grippers

- Intelligent Actuator

Electrical & Controls

- Allen Bradley – PLC’s, Drives & Terminal Blocks

- Siemens – PLC’s

- Hoffman Enclosures

- Cognex Vision Systems

- Keyence Sensors

- IFM Effector Sensors

- Turck i/o

- Banner Safety

- Sick Safety

- Fortress Locks

Pneumatic

- SMC Pneumatics

- Festo Pneumatics & Actuators

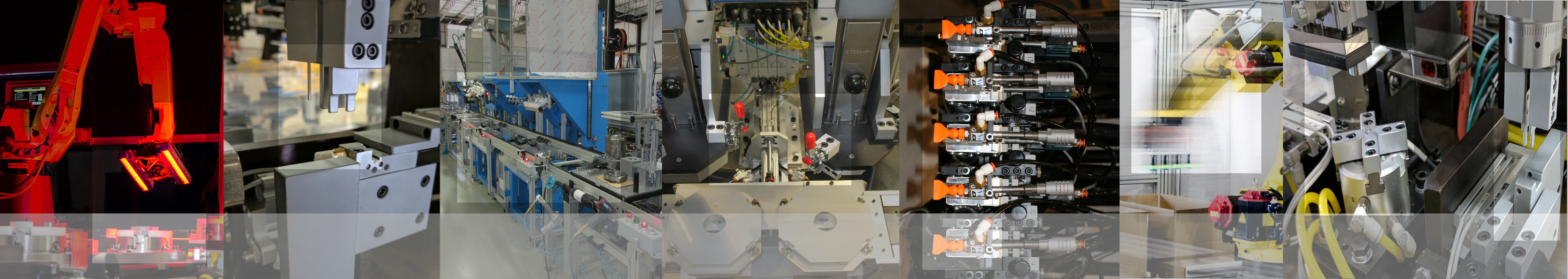

Projects with Robots and Dial Machines

ProMATIC Automation can integrate robots from any manufacturer. Featured in this video are Fanuc Robotics, Motoman / Yaskawa Robotics and Mitsubishi Robotics. ProMATIC is well equipped to integrate other robot brand such as ABB, UR, Kuka and many others.

Dual Head Trumpf Laser Marking(Etching) Machine

Since the year 2000 ProMATIC Automation has built a variety of Laser Marking equipment. Some laser markers are part of a larger system that etch a serial number and 2D Barcode on parts. Dedicated laser marking cells may use multiple marking heads to etch graphics on to stainless steel panels. The video below demonstrates the use of a dual head Trumpf laser marking system to etch our company logo onto a piece of 304 Brushed SS. The process takes approximately 4 minutes but the video has been cut to show the major steps.

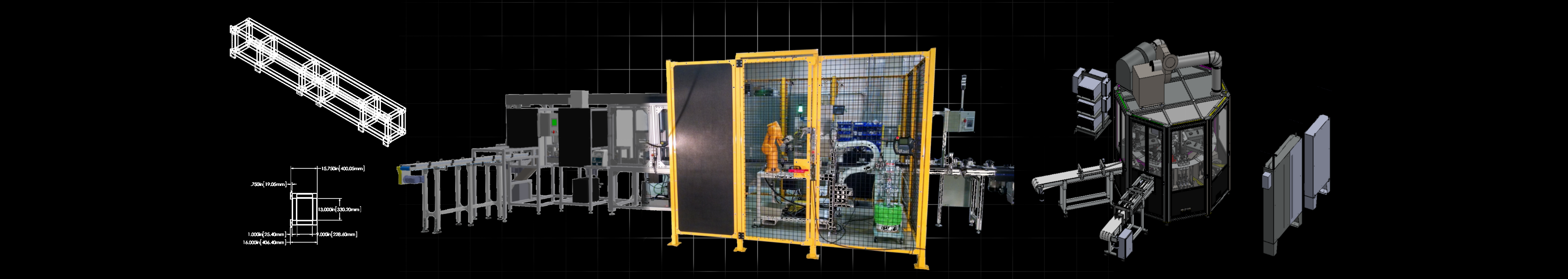

Bin Handling Equipment

ProMATIC Automation has developed a full line of large bin handling equipment. The equipment in this line is used to automatically setup and prep bins for manufacturing and then collapse them for storage. ProMATIC also has designed a tote sorting system ideal for an automated shipping warehouse .

- Collapsed Bin Stacker & Destacker

- Collapsed Bin Erector

- Bin Inverter

- Bag Inserter

- Pile Leveler & ALIS (Automatic Lid Installation System)

- Bin Collapser

Collapsed Bin Stacker & Destacker

- Flexible Design for Multiple Bin Types

- Robust Construction

- Works with Existing Conveyors

Collapsed Bin Erector

- Configurable EOAT for Multiple Bin Types

- Wall Latch Verification

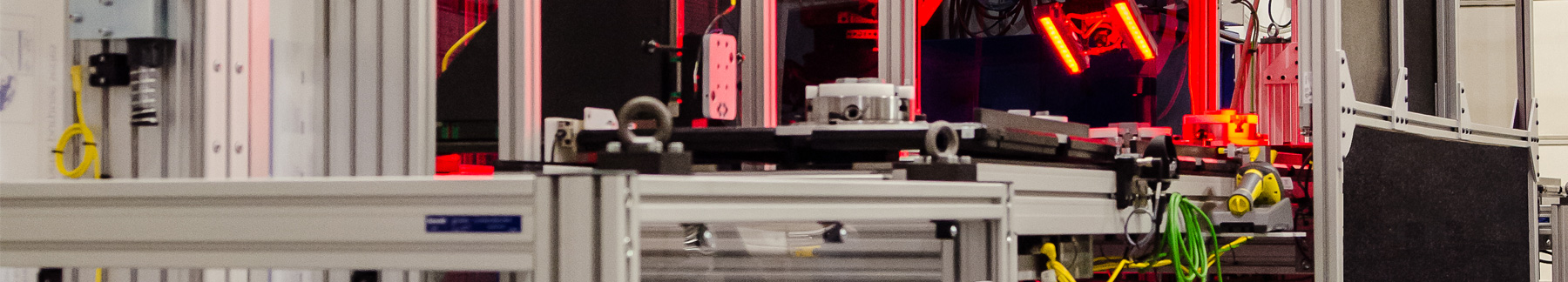

Bin Inverter

Used for cleaning out an empty bin. Ion canons blow out the contents of the bin with deionized air.

- For Leftover Product & Debris Removal

- Fully Electric Mechanism

- Optional Deionizer Blowout

- Design Variations for Multiple Bin Types

Bag Inserter

- Automatic (Socking & Cinching) to Secure Bag

- Bag Spreading

Pile Leveler & ALIS

- Configurable for Multiple Bin & Lid Types

- Automatic EOAT Changer

- Can Also Be Used as a Lid Remover

Empty Bin Collapser

Bins are transferred on conveyors (not shown) and stop under the inverted robot. The robot releases and collapses all four bin walls. They bin is now ready to be stacked and stored.

- Configurable for Multiple Bin Types

- Variable Wall Collapsing Order Possible